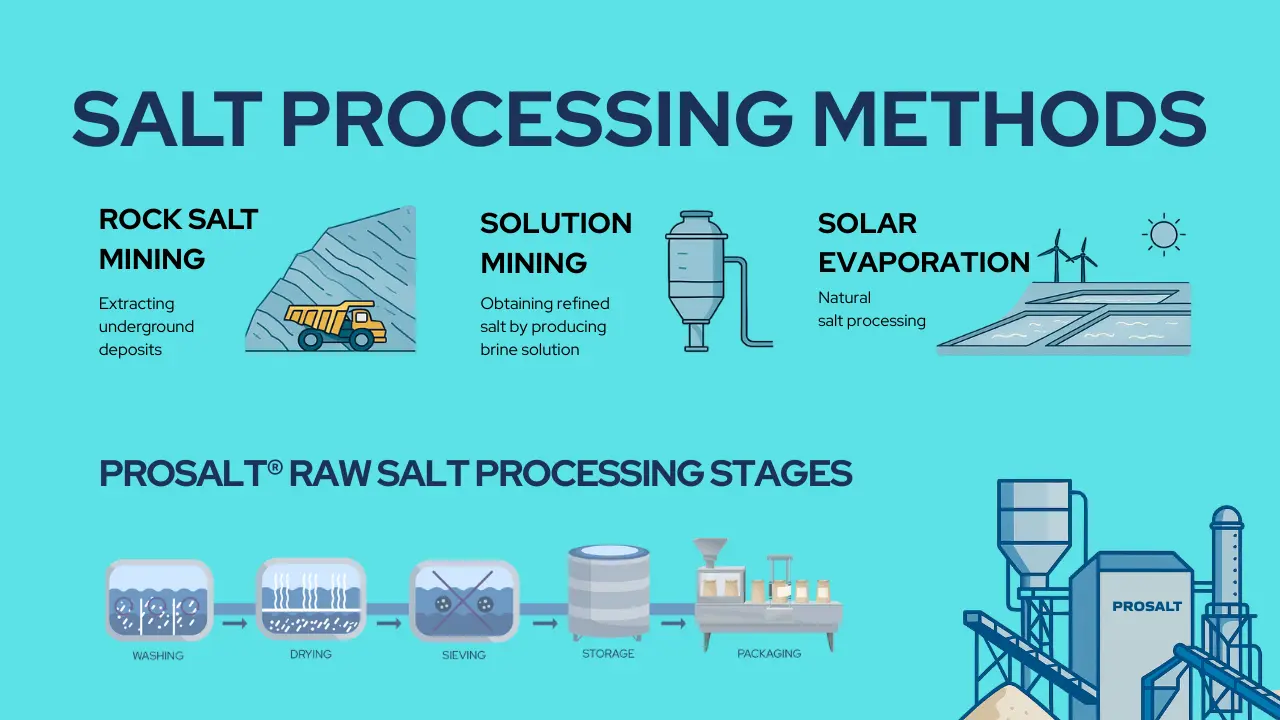

Salt processing is essential for obtaining a high-purity product used in the food, chemical, and pharmaceutical industries. Natural salt processing methods differ, from extracting underground deposits to evaporating seawater.

In this article, we explain in detail how salt is made and the processes for various applications.

Salt is extracted from underground deposits, mineral reserves, and seawater. Depending on the source, the salt processing method varies to guarantee maximum efficiency and purity.

One of the most common ways to understand how salt is made is rock salt mining. This process involves extracting salt from geological deposits formed by the evaporation of prehistoric seas.

Salt processing in rock mining:

Another key method in salt processing is solution mining, used when salt deposits cannot be extracted through conventional mining.

How salt is made through solution mining:

Solar evaporation is the oldest and most eco-friendly method within salt processing. It relies on the sun and wind to evaporate water and obtain salt crystals.

Salt processing through solar evaporation:

To ensure the highest purity and quality, PROSALT salt plants use a three-stage refining method:

Washing: The raw salt undergoes multi-stage washing to remove both soluble and insoluble impurities. This results in cleaner, high-grade salt suitable for food and industrial use.

Drying: The washed salt is dried using advanced drying technology, reducing moisture content and preventing clumping, ensuring long-term stability.

Sieving & Packaging: The refined salt is carefully sieved to achieve uniform particle size before being packaged for various industrial, chemical, or food applications.

This three-stage salt processing method guarantees high purity, consistency, and superior quality, making it ideal for a wide range of industries.

Salt processing is crucial for various industries, as it ensures a product with the appropriate purity and granule size for each application.

Food Industry: Salt is an essential ingredient for food preservation and flavor.

Chemical Industry: Used in the production of chlorine, caustic soda, and other chemical products.

Pharmaceutical Industry: High-purity salt is crucial in medical and laboratory applications.

Water Treatment: Used in purification and water softening systems.

Salt processing has evolved over time, integrating advanced technology to improve efficiency and product quality. Understanding how salt is made helps to recognize the importance of each method and its impact on the purity and sustainability of the final product.

If you want to learn more about salt processing, keep exploring specialized content and discover innovations in the salt industry.

With a focus on technical excellence, PROSALT continuously innovates to refine salt processing methodologies. Our state-of-the-art facilities deliver superior products while maintaining sustainability and cost-effectiveness.

Whether for industrial, chemical, or food applications, PROSALT ensures high-purity, consistent salt backed by precision engineering. Contact us to learn how our solutions can optimize your salt processing needs.

تضع PROSALT، بصفتها العلامة التجارية الجديدة لشركة Yiğitbaşı لماكينات الملح

تضع معيارًا جديدًا في عملية إنتاج الملح الخام بخبرة وخبرة ٤۰ عامًا.

ويظل التزامنا برضا العملاء أمرًا بالغ الأهمية حيث نسعى جاهدين لتجاوز التوقعات.

املأ النموذج أدناه وسنتواصل معك.

اتصل بنا

يمكنك التواصل معنا في أي وقت.